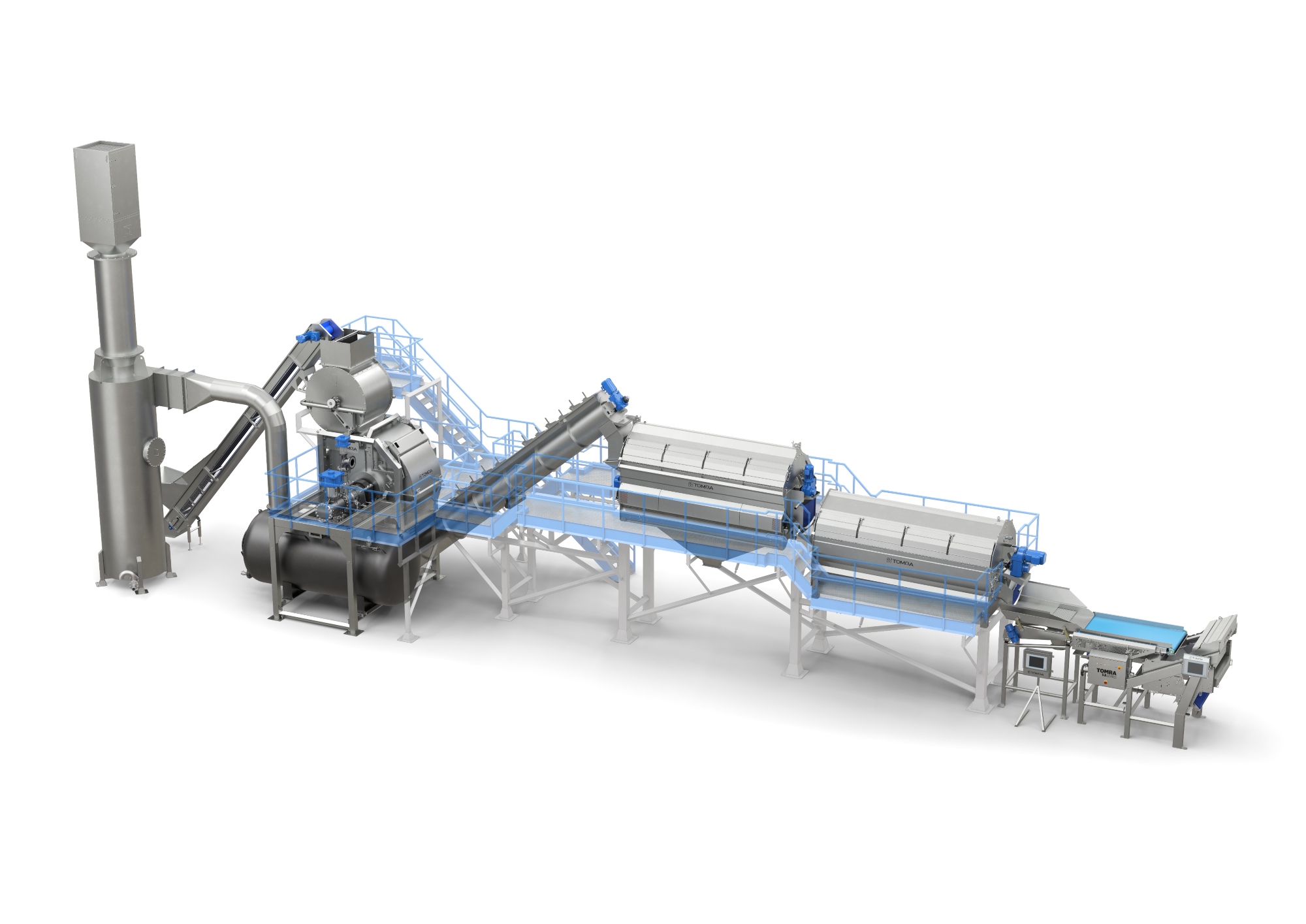

Steam Peeling Line

The most trusted steam peeling solutions in the market

-

500+ steam peelers in operation worldwide

-

#1 steam peeler supplier in the world

Harnessing the most reliable processing line for your food business is essential for success. TOMRA's Steam Peeling lines better manage resources, reduce waste, and enable processing efficiencies you never knew existed.

We transform global potato and vegetable production, maximizing food safety and minimizing food loss.

Listen to what our customers have to say

.jpg?hash=919d65528d68737307c5b366f7f9faf9da164498694772a9eeaf23025c2a8fe7&w=460&h=250&q=75&fit=crop&format=webp)

Lamb Weston - Meijer - Potatoes - The Netherlands

Click the touchpoints to learn more about the features of the peeling line

TOMRA XP & XPT Expansion system (patented)

Food industry fastest steam delivery system to ensure fast steam transfer to the peeling chamber. TOMRA industry leading steam valves design deliver high wear resistance and rapid pressure release for uniform skin separation.

High accuracy rotary batch weigh unit

Full stainless steel, multi-vane weight unit with direct drive SEW IE4 motor. TOMRA weighing module with multiple sensors for optimum accuracy, performance, and control.

TOMRA pressure vessel (patented)

Unique vessel design to ensure maximum mixing and fast steam treatment. TOMRA vessel shape delivers the fastest product exit which avoids large cook ring.

Discharge chute and elevation auger

Bespoke design of chute to capture the vegetables exiting the peeler vessel. Unique design features to achieve gentle product handling and prevent product damage.

TOMRA Care

TOMRA Care experts provide customer support in the event of breakdowns to avoid production stops or interruption due to a defective machine.

TOMRA Dry peel separator

TOMRA Model OB Brusher

High capacity U-trough brusher to provide additional mechanical action to remove loose peel and minor surface defects. Adjustable to achieve exact performance required.

TOMRA Model OW Washer

Stainless steel drum separator with perforated screens and customized slot pattern to achieve zero peel loss. Additional water reclaim and filter unit to capture waste water.

Peel to Spec module

TOMRA’s Peel to Spec module seamlessly integrates all machines across the processing line to reduce energy consumption and delivery quality output according to the customer's specifications.

TOMRA 5A Whole product sorter

The TOMRA 5A sorting machine brings more than 98% removal rate of foreign objects, quality inspection and peel quality control to the table. Running the highest capacities in the industry, this process potato sorter significantly increases the level of food safety and yield.

Peeling digital hub

Network communication and digital nerve centre for the automatic processing of a wide range of Potatoes and other root vegetables.

Our peeling equipment processes 75% of the french fries worldwide every year, but don't let that fool you. Our partners need versatility, so our solutions are just as efficient with apples, carrots, peppers, peaches, pears, and sweet potatoes. We are designing Steam Peelers that our partners continue to trust to make their job easier. Want to learn more?

Get in touch

Operational costs continue to increase, and every little saving makes a difference.

Our automation works smarter, wastes less, and optimizes your lines to ensure quality is consistent and potential recalls are a thing of the past.

Speak with us to learn how you can make Every Resource Count!™

In the spotlight: steam peeling

How the best steam peelers can significantly reduce food waste on vegetable processing lines